Product Name:Perforated Aluminum Panels

Brand:Guangdong Reinalite Industrial Co.,Ltd

Material:3003H24/1100H24 aluminum alloy

Color:customized design,choosed from RAL catalog

Surface Treatments:

1,Powder coated(Ordinary PE / Fluorocarbon powder)

2,PVDF(PPG,AKZO)

Pattern:Customized Design Available.

Thickness:customized design

Thickness:customized design

Process Equipment:CNC punching machine/ engraving machine

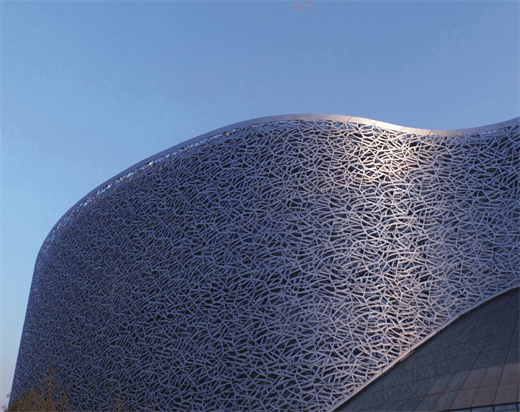

Application:outdoor & Indoor decoration

Warranty:Up to15 ~20 Years

Monthly Capacity:50000 square meters

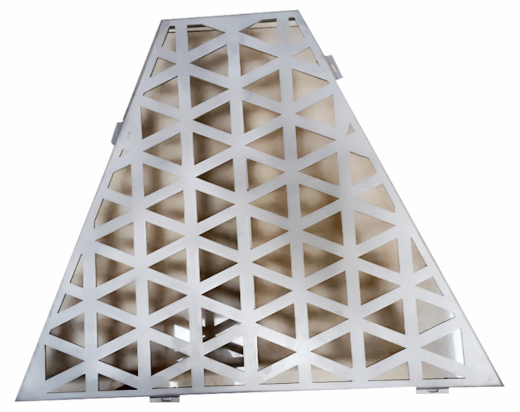

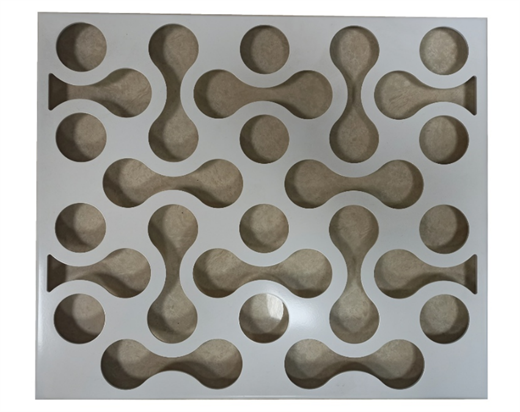

The hollow plate is a personalized pattern of different shapes processed by CNC engraving machine and CNC turret punch.

The surface can be sprayed, oxidized, etc. The combination of hollow board and other decorative materials shows more fashion

and individuality. It creates more imagination space for designers. Different designs create different decorative effects.

The extraordinary design gives it a value-for-money effect.

The surface can be sprayed, oxidized, etc. The combination of hollow board and other decorative materials shows more fashion

and individuality. It creates more imagination space for designers. Different designs create different decorative effects.

The extraordinary design gives it a value-for-money effect.

· Light weight, good rigidity and high strength

· Good sound /heat insulation and shockproof performance

· Flame-retardant, anti-corrosion, moisture-proof

· Environmental protection, not easy to age and deform

· Easy assembly and disassembly, convenient maintenance

· Diversified styles, patterns can be customized

Building exterior walls, beams and columns, balconies

Terminal/car building

Conference hall, opera house

Sports venues, KTV clubs

Reception lobby etc.

1. The hollow aluminum veneer system is installed with the corners according to the same level.

2. Hoist the light steel keel (38 or 50 keel) according to the appropriate spacing, the general spacing is 1-1.2 meters, and the distance of the boom is distributed according to the light steel keel regulations.

3. The hollow aluminum veneer system puts the hanging parts pre-installed on the aluminum veneer keel, together with the aluminum veneer keel, is closely attached to the light steel keel to be buckled under the light steel keel in a vertical direction. The distance between the aluminum veneer keel is determined by the size of the plate. OK, it must be adjusted to the level after all installation.

4. Buckle the aluminum veneers on the keel in sequence, and press down the inverted lock piece after each piece is buckled. When the keel is connected, use the connecting piece to connect.

5. When installing the fireproof aluminum veneer system, you must wear gloves. If fingerprints or stains are left accidentally, they can be cleaned with detergent and wiped dry.